Click here for more details.

Textile Electronics

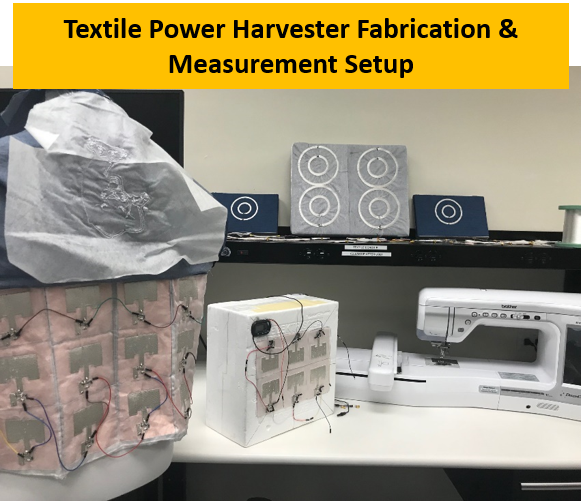

Our group has developed a new class of electromagnetically functionalized garments that have excellent electrical and mechanical properties. These electronic textiles aim to provide a new paradigm in addressing a multitude of wireless connectivity for healthcare applications. Our fabrication process is based on automated embroidery of metal-coated polymer E-fibers, down to 0.12mm in diameter. The employed E-fibers are silver-coated p-phenylene-2,6-benzobisoxazole (PBO) or liquid crystal polymer (LCP) filaments bundled into groups of 7s to 600s to form threads for use in programmable sewing machines. These textile surfaces feel and behave like any other clothing. At the same time, their RF performance is as good as that of copper, even after 10s of washings. Our automated embroidery process is not limited by thickness or material types.

Our group introduced a new class of textile antennas on polymer substrates. Such a unique combination offers excellent RF performance, mechanical strength and flexibility for emerging structural conformal and multi-functional RF designs. Example applications include but are not limited to: a) textile antennas integrated upon several everyday garments; including suits, shirts, and scarfs, b) textile-based RFIDs, c) stretchable and flexible textile antennas embedded in polymer for operation in harsh environments (e.g., automotive, implantable, wearable, etc., d) body-worn medical sensors (e.g., deep-tissue imaging sensors), and e) textile antennas for integration into vehicles, particularly small air and ground vehicles.